I want more power!

OK, how do we decide how much and how we're going to add it? If you intend to use

the engine with an auto gearbox and/or a heavy vehicle, your options are fairly restricted. Autos

don't work too well with more radical tuning, where the torque is rather limited

below 1000rpm. This is likely to be a particular nuisance on the 3.5 litre engine

although it applies to all. Because the torque converter introduces drag on the engine

at low rpm it can cause nuisance stalling in traffic and at idle. With a heavy vehicle

like a Landrover you really want lots of grunt to get things moving although if you

use a manual gearbox, you can opt for a more radical camshaft without making the

engine fussy and difficult in traffic because the engine turns freely at idle. With

the right cam, some headwork and fuel injection or decent carburettors and a good

exhaust system), you can build a 3.5L engine that will make 200BHP+, have huge midrange

torque and still be friendly to drive. Obviously the bigger engines can make proportionally

more and will take wilder cams, since the low speed torque will still be comparable

to the smaller engine and because they tend to soften the cam characteristics anyway.

Bigger EnginesHowever, if you want substantially more torque at low to midrange rpm

(idle-

Factory Inlet and Exhaust Manifolds

Lets go back to our well prepared engine with the standard cam. This is quite a potent package but is let down immediately by what you bolt onto it in the way of manifolds, carbs and exhaust. Lets take a look at the standard bits first.

Exhaust ManifoldsStandard exhaust manifolds have two patterns, single branch and double branch outlets. Generally, the single branch ones work well at low speed but put a severe crimp on performance at higher speeds. If the twin branch ones can't be fitted instead then the best option is an aftermarket tubular 4 branch manifold. Early range rovers and defenders can accomodate the two branch systems and these work very well, even on bigger engines, but will reach their limits past around 200BHP. They can be improved by grinding the ports but it's hard work and easier to go for a four branch manifold.

SU CarbsSU carburettors and Solex/Strombergs are a very common fitment to these engines. I think the SU's work best although they may not be quite as accurate, plus they tend to work well at crazy angles. Properly set up SU's, with the correct jets and modfications to the throttle plate are capable of over 200BHP and offer good torque using the standard manifold with some porting. The throttle plate has a bypass valve which should be soldered shut and the spring and pin removed, the screws securing the plate to the spindle can be loctited and trimmed to match the spindle.

Improving the std carb manifoldThe carburettor type manifold is actually a rather good design and is optimised for bottom end and midrange torque. Again it can be improved by matching to the ports and some internal tidying, especially around the raised pentroof area. This can also be machined out to 2' and given much nicer curves. The carbs and phenolic spacers will need to be blended to match and the swirl device should be dumped and the one designed for HS8 SU's used instead (as used on the straight 6 Jags). You can also use these spacers instead if you wish.

Aftermarket Induction Options

If going for aftermarket carbs, manifolds and exhausts, careful consideration should be made of the kind of use and performance you expect from the engine, as these can have a striking effect on bottom end torque, top end power and economy. Some after market carbs are also tricky to set up and keep in tune and some may not fit under the bonnet of standard vehicles. There are several alternative carbs to fit the V8 and a choice of manifolds as well. The common ones are the Weber dual downdraft on a modified standard manifold, which, frankly is crap.

RPI Boxer

Then there's the Boxer manifold with 4 SU's mounted on it, which isn't much better. Although capable of good torque across the range, it suffers from several glaring design problems and is a real pain to keep in tune.

Edelbrock 500The Carter/Weber/Edelbrock 500 and Holley 390 or 465 four barrel carbs offer good performance, fit well and have fairly acceptable economy with parts available for LPG use as well. Once set up correctly they tend not to drift out of tune. The Carter, Weber or Edelbrock carb on an Edelbrock or Weber dual plane manifold is about the best all round combination, with the Holley more suited for racing and larger engines. There are single plane manifolds such as the Huffaker available as well but these are really only suitable for very high revving engines and have no provision for heating or a thermostat. As with the standard manifold, there are benefits in blending and smoothing the ports and runners.

Downdraft Carbs

The only other arrangements worth mentioning are the 4 way dual downdraft Weber or Dellorto setups. These use dual downdraft carbs with one carb per cylinder and can give outstanding results for almost any application through selection of the venturi size and ram. Possibly the ultimate and most expensive carburettor based solution, there are still a surprising number around and work extremely well although they do require frequent adjustment and can be appallingly thirsty. They do look and sound the business though. In general more/bigger carbs will increase fuel consumption as well as power.

Fuel Injection

There is also the EFI option. In general, these will outperform all carburettor systems in all areas and can support engines producing well in excess of 300BHP with little modification. Various systems are common, Lucas airflap and hotwire, Bosch, GEMS, and to a lesser extent the after market Motec and similiar fully mapped systems. Airflap and hotwire are covered in a later section, GEMS and MOTEC are specialist areas. The manifolds for any of these also benefit from the usual matching and blending.

EFI Plenum Options

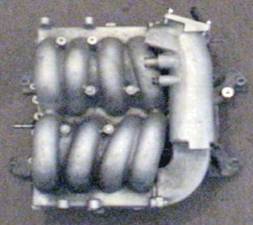

A plenum is the chamber behind the throttle each cylinder draws air from via a trumpet

or ram, which is on the end of the inlet tract. Specific to EFI systems, they are

designed to smooth out the induction pulses so that the throttle and airflow meter

see a more continuous flow rather than a stream of pulses of air as each cylinder

breathes. This what the various production V8 plenums look like. The second image

also shows the trumpets. All these configurations are vastly more efficient than

the twin carburettor set-

Single throttle plenum used on most EFI V8 engines; max 250bhp in standard form but capable of great improvement. Uses Lucas parts. Works racing twin throttle plenum + trumpets used in works touring car and works rally championships for 350bhp+. Capable of tuning to suit application. Uses Lucas parts. BMW designed single plenum as used on late 4.6L Range Rovers and Discovery’s, max 270bhp but very good for low/mid range torque. Limited usefulness at high rpm. Very difficult to modify for better performance. Uses Bosch parts. The ones tested in the dynometer charts (next section)look like this:

Twin plenum, triple plenum and triple plenum installed on a Westfield racer. For engine outputs from 250bhp to 400bhp or more. Various trumpet options and throttle sizes available to suit application. I know there are many people out there who love carburettors and wouldn’t swap them for EFI if you paid them, but if you want real power, economy and reliability there is really no alternative these days. The commonest argument is that you can’t adjust them or fix them easily. Really this is only partly true. Firstly, if you need to alter them to compensate for major engine modifications it is perfectly possible and cheaper than fitting suitable carburettors. Secondly, they should never need periodic adjustment other than a very rare tweak to the CO setting and idle speed both of which are accessible if required. Fault diagnosis of an EFI system is usually quite straightforward if you take the time to study how it works although actual repair of an ECU may be a specialist thing but needn’t be very expensive.

Eliot's note: Megasquirt is inexpensive, cheap and ideal for Rover V8 Engines. If we were to take our nicely prepared engine with our standard camshaft and fit a gas flowed Edelbrock manifold and correctly jetted Weber carb, with standard dual branch exhaust with a low back pressure silencer, I would expect to see somewhere in the region of 180BHP and good torque from idle to 5500rpm with a maximum of around 225lbft. Possibly a little more if the cylinder heads are very tidy and probably a bit more if we had EFI fitted instead.

Camshafts

Let's see whatc hanging the camshaft could do for us. First off, the actual shape

and range of the torque curve is primarily determined by the camshaft. The upper

limit will also be determined by the valves and ports and greatly by fuelling arrangements

such as the size of carburettors and exhaust dimensions. The porting and valve sizing

can also influence the low to midrange to some extent as can design of the exhaust

system. Most camshafts produce between 75%-

The relationship between power and torque

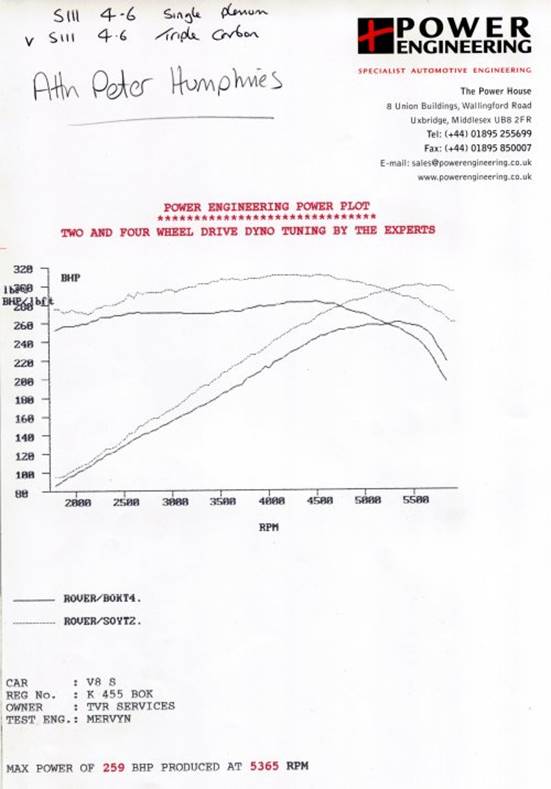

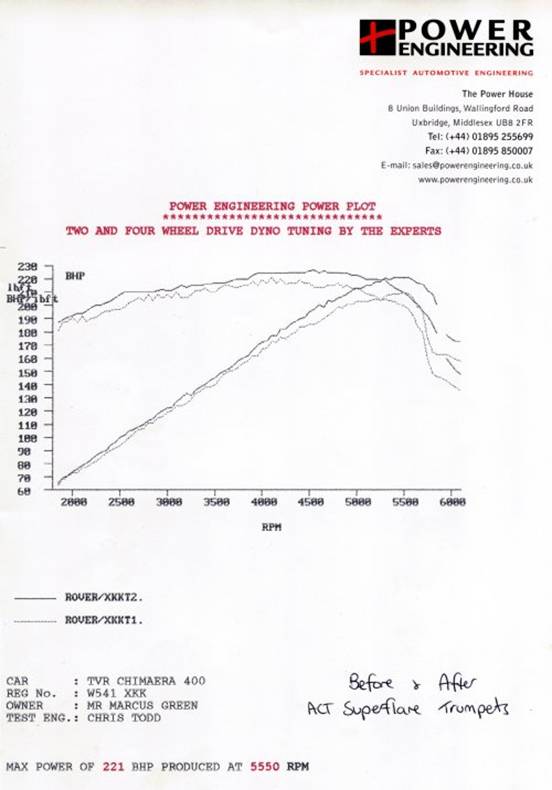

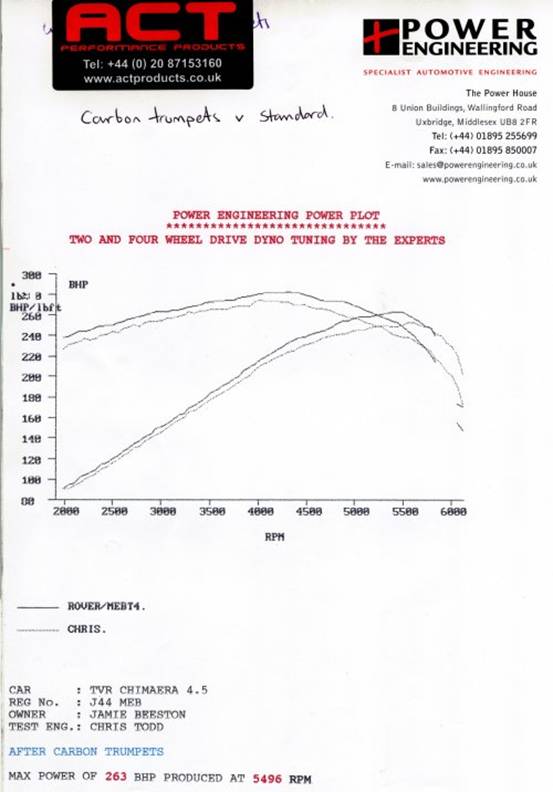

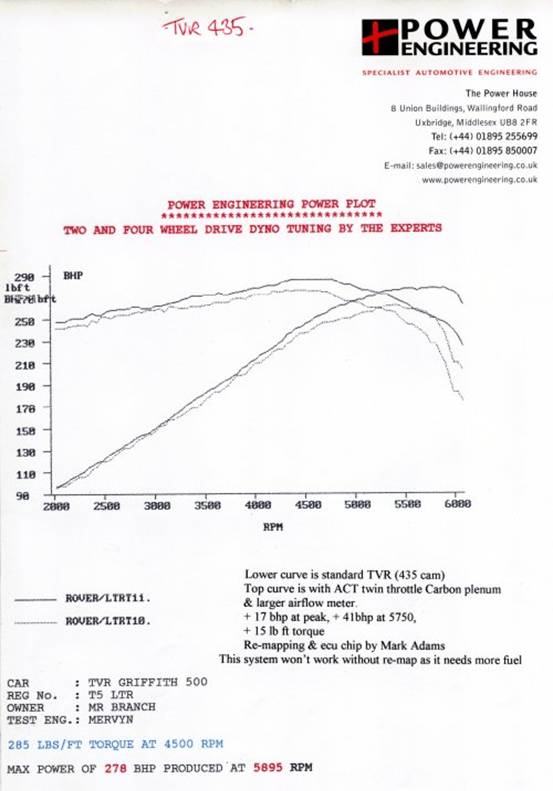

Below are a few dyno charts showing the relationship between power and torque from 5, 4.5 and 4.0 Litre V8 engines which are already in a healthy state of tune and use airflap or hotwire EFI systems. These charts also show the effect that improving the breathing has on performance, one of the biggest issues with this engine, along with a selection of different performance camshafts. These charts are from Tim Lamont of ACT Products, who make advanced carbon fibre plenums and rams (trumpets) shown above.

Although these plots are mostly from TVR supplied engines, there are no fundamental differences between any of the Rover V8 engines whether they are used in a Morgan, TVR, Rover/MG, Landrover/Range Rover or anywhere else. All the extra performance is derived from the various factors discussed in this document. In practice, these engines are usually interchangeable between models and manufacturers as well. No great challenges await the person who wants to drop a TVR Tuscan engine into his Defender 110.

Understand your requirements

So lets be realistic and accept that we want a smooth, slow idle with good torque from low revs. In fact, what we usually want is maximum torque at low revs, consistent with a wide power band for good flexibility with good economy. There is a compromise here as you can see. Position maximum torque at say 2000rpm and we'll have an engine that can spin the wheels from idle but goes gutless at 4000rpm (rather like the early production camshafts in fact). Camshafts control this characteristic in a number of ways, one is by altering the maximum valve lift away from the standard 0.39"; to as much as 0.6" and the other is by altering the timing of the opening and closing of the inlet and exhaust valves. This will affect either the duration of opening or by the amount of overlap, which is the amount of time both valves are open at the end of the exhaust stroke and the beginning of the inlet stroke. Clearly if both valves are open when the piston is approaching the top of the bore at the end of the exhaust stroke, there is scope for an expensive collision and this needs to be considered when deciding how much lift and overlap are used.

High lift

Some high lif cams do require pockets to be machined in the crown of the piston to avoid this possibility. The other issue with lift is that high lift cams can place enormous stresses on the valve gear and may cause the valve cap to strike the top of the valve guide or cause the valve spring to become coil bound. These also need to be considered and in practice, any cam that uses lift in excess of about 0.44" may require work to avoid all these issues. As a consequence, the majority of fast road/rally hydraulic cams use lifts around 0.43". Obviously more lift means less interference from the valve head in the airflow through the port/valve seat area and into/out of the cylinder but we have to live with the compromise. Due to the need to minimise stress on the rocker gear, higher lift also implies longer duration. This is because the shape of the opening and closing ramps on the camshaft have to be carefully controlled to avoid valve bounce and excessive wear or shear forces in the rocker gear.

Followers

Standard cam followers are hydraulic and take up wear and clearances by pumping up an internal plunger with oil. Many high lift cams do not work with hydraulic lifters (followers/tappets) and will need to use solid lifters and adjustable pushrods or adjustable rockers. There are obvious benefits to using cam profiles that don't need manual adjustment periodically. However, hydraulic cams are a compromise and the best result will always be obtained using a solid lifter camshaft with roller lifters since the ramps can be optimised for controlling the valve opening and closing rather than looking after the hydraulic lifter. Roller followers and solid camshafts can be extremely reliable, but require periodic adjustment of tappet clearances. That said, the best hydraulic cams produce very good results not far off those of the milder roller lifter/solid camshaft combinations. For the vast majority of engines, solid camshafts are either not necessary or even a nuisance, since outputs approaching 300BHP can be had with a suitable hydraulic design. Overlap

With overlap, there are compromises too, more overlap means better cylinder filling at high revs, with a loss of efficiency at low revs as there is a tendency for excessive intake charge to disappear down the exhaust port with consequent inefficiency and loss of economy. We can mitigate this to an extent with correct selection of the exhaust system and some porting techniques.

Idle Quality

However,as the inlet port opens earlier and closes later because of the longer duration, there is a tendency for charge contamination to occur as exhaust gas enters the inlet port and a reduction in engine vacuum as flow reversal occurs at the end of the inlet stroke, which is ultimately the cause of the rough idle with high performance cams and the loss of low rpm torque. As a consequence of all of these effects, the most practical (not the most powerful) cam to use is one with moderate lift not exceeding 0.43", which has faster ramps to reduce duration and more overlap. In addition there are one or two things we can do in the ports to reduce the flow reversal and back pressure issues and in the exhaust system itself. More on this later...

Aftermarket Bolt-

Many mild cams fit into this category, currently I know of several, almost all of

which will bolt in without any further modification. Of these, 5 work well in the

1500-

Progress Engineering's RC87, RPI's RP4,

JE Engineering's JE101

Real Steel's Hurricane and the Piper H200. These camshafts all work with absolutely

standard engines and standard cam gears, chains, etc, although preload (shimming)

should be checked and it is preferable although not essential to use hi-

I’d recommend the RC87 as the best all round. It works extremely well in standard engines with standard exhausts and turns into a wild thing if other tuning steps are carried out. In practice, it moves the tuning onto exhaust and inlet systems in a very nice predictable way so it becomes easy to tune to whatever level you need without messing around with the camshaft. It’s possible to get 220+bhp from a 3.5L V8 with airflap EFI on this very civilised camshaft if the porting is up to scratch. If considering turbo or supercharging then this is as radical as you should go and raising the compression ratio at this point is not an option. In fact, I'd probably choose a camshaft with a shorter exhaust duration for these, possibly the standard camshafts or one specifically designed for forced induction. On a standard 3.5 you could expect to see at least an extra 15BHP by virtue of the change in the position of peak torque and the extra torque available at the top end with any one of the cams listed above and no other modifications. Rather than our original 205lb/ft at 2500 rpm and 170BHP at 5000 rpm we should have rather more like 225lbft at 3000rpm and 185BHP at 5500rpm, rather similar to the standard 3.9 engine. The downside is that you may have rather less torque at 1000rpm, however, at 1500rpm you will have slightly more than you did before. Our engine sporting a 4 pot Weber and a decent exhaust system could see nearly 200BHP and an EFI system could be getting 240lbft of peak torque and over 200BHP with little loss of bottom end torque. In fact, the best EFI systems can make 220+BHP with a mild cam but it takes a fair bit of porting and some care with the inlet and exhaust dimensions. Obviously it is possible to get more torque and power, much more actually, but you need to start doing some serious headwork to accommodate the next range of cams and you need to be prepared for a slight loss of torque and from idle to 1500rpm or so. Most of these cams are not suited to automatic gearboxes and one or two may result in a choppy idle.